Ladder jack scaffolds are quite affordable and portable, which makes them a top priority for most ladder users. Even more, you can use a ladder jack scaffold to perform a variety of tasks, such as painting buildings, building exteriors, among other things. In this post, I’ll be walking you through how you can use ladder jacks in line with Occupational Safety and Health Administration (OSHA) guidelines.

Table of Contents

What’s a Ladder Jack Scaffold?

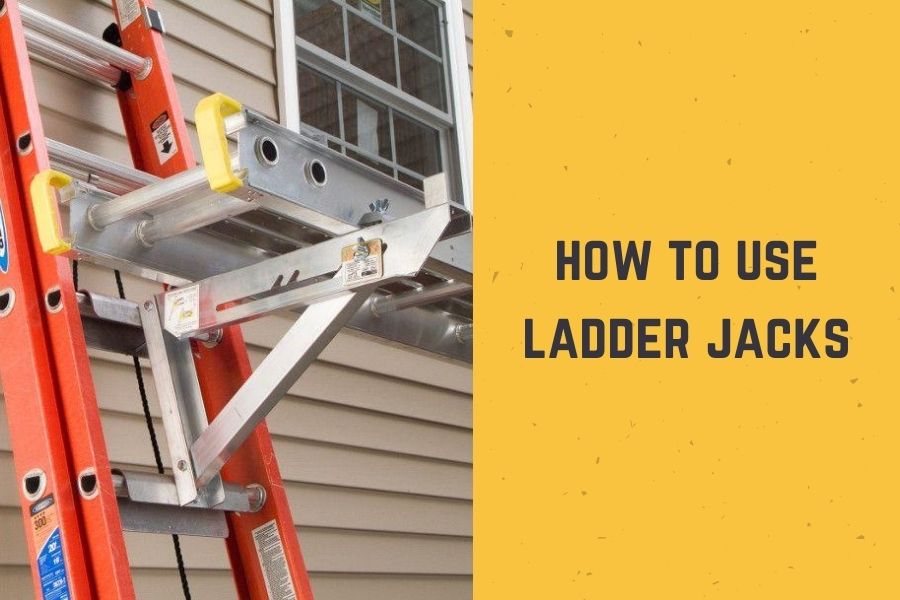

A ladder jack scaffold is a tool with a resting platform on the brackets usually joined with a ladder. In most cases, contractors use ladder jacks for light operations because they are easily portable and their affordability. They are triangular and are joined to two other ladders (portable) to provide support as you work. There are two common types of ladder jack bracket tools, which I have discussed below:

- Side Rail Ladder Jack Tool: The side rail ladder jack tool is joined together with an extension ladder (you can use a single ladder) and a railing. Once you have joined them, create a work platform by sliding them into the right position.

- 2 or 3 Rung Bracket: For this ladder jack, you will directly link it to the 2 or 3 ladder rungs. Once that is done, place the planking at the top of your brackets to have a working platform.

Now that you understand what a ladder jack scaffold is let’s now move to what you need to do before using ladder jacks, according to the OSHA guidelines.

How to Set Up and Use a Ladder Jack

Before you begin using your ladder jack scaffold, there are a few things you need to make sure the following:

- First, you need to make sure that your extension ladder is not separated to help you create 2 ladders.

- Next, you need to clear the area you will be working on and make sure that it’s clear from sharp objects and any other dangerous items.

- Check your scaffold and confirm if there are any damaged parts and that they are in good condition, ready for work. If there is any place that needs to be tightened, please do so.

- If in any case, you will need substitute pieces, plan early to acquire them and ensure that the pieces are not cracked, bent, or even vandalized in any way.

- If you intend to use the 2 or 3-rung jacks, please make sure that your rectangular brackets can fit well into your ladder rungs.

- If you use the side rail brackets, you’ll first need to make sure that the upper round hooks and your lower brackets are safe. Next, rest your brackets on your rungs then make sure that the platform is secure at the adjustable notches.

- Make sure that the bracket jack is adjusted to a parallel position to the ground.

- In case you find any defective part of the scaffold, make sure you have removed and replaced it before you begin working on your ladder jack scaffold.

- Make sure that you have tightened your jack’s wing nuts to avoid slipping when working.

- Avoid using metallic ladders if you will be working around power lines.

- Make sure that you are working on a leveled ground. If at all you are located in an area with the sloppy ground, try and level it before you begin working.

Apart from the above recommendations, it would help if you made sure that the area you will be working on is level and free from sharp objects. If the area is crowded with unnecessary equipment, please clear the area before you start working.

Additionally, OSHA has warned against setting up a ladder jack scaffold in busy areas. Also, it would be best if you used slip-resistant feet to make sure that your ladder is secure. Finally, it would help if you were extra careful when working around hazardous areas, such as near power lines, etc.

And that’s it. So how do you use the ladder jacks once you have ensured that everything is working perfectly?

General Precautions

- Don’t ever set up a ladder and leave without using it. Additionally, keep away children from ladders.

- Keep away all foreign materials from your ladder jacks.

- Do not use a ladder if you are feeling unwell to avoid unnecessary accidents.

- If you intend to work on a windy day, make sure that you are more careful to avoid accidents.

- Keep your body weight between the rails and make sure that you are safe when working on the ladder.

- It would be best if you made sure that your shoes are clean.

General Set-Up and Usage Instructions

- There are only a few ladders recommended – 375-pounds (IAA), 300-pounds (IA), 250-pounds (Type I).

- Make sure you have followed to a tee all the instructions given by the manufacturer.

- Position your ladders at the right angle.

- Secure the bottom and top of your ladders before you can join them with your ladder jacks.

- Every hook should engage a rung.

- Keep adjusting the brace until you attain a horizontal surface. Also, make sure that you have engaged and locked the adjusting mechanism.

- The width should be 12 inches and the wood platform 18 inches.

- The height should be at 20 feet from the ground at maximum.

- Your platform should overhang your support by either 12 to 18 inches. Also, it would help if you never used the overhang.

- Opt for toeboards or guardrails if you will be working on a height of 10 feet or more from the ground.

- You must ensure that your set up and usage conforms to the standards set by ANSI and OSHA.

You now know most of what you should do – from how to set up a ladder jack to how you can use it. However, there are a couple of questions that most people still ask. Let’s look at some of them.

Frequently Asked Questions

1. How Can I Use a Ladder Jack?

You can use ladder jacks to run planks between single or extension ladders. Make sure that you place your ladder jacks 1 ft from the plank end. Additionally, make sure that you are using either Type I, IA, or I AA ladders.

2. Does OSHA Approve Ladder Jacks?

There are still many standards by OSHA that ladder users should adhere to when using ladders. For example, users should be protected if they are working on 10 ft or more. You can also check above to see some of the guidelines that they recommend.

3. What Plank Width Should I Use On a Ladder Jack Scaffold?

18 inches is the minimum width you should use. You can also check what OSHA, ANSI, and the local codes in your state say about the plank width required.

Bottom Line

So you now know how you can set up a ladder jack, use it. You also know some of the precautionary measures put in place by OSHA, ANSI, among other regulatory bodies. It’s time to take action. Get your ladder jack scaffold and get to work.